Voltage Controlled Pwm Driver

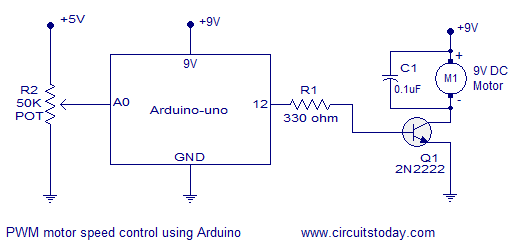

DC Motor Driver circuits. Why is there a need for a motor driver circuit Normal DC gear head motors requires current greater than 2. A. ICs like 5. 55 timer, ATmega. Microcontroller, 7. ICs cannot supply this amount of current. If we directly connect motors to the output of any of the above ICs, they might get damaged. There is a need of a circuitry that can act as a bridge between the above mentioned ICs and the motors. There are several ways of making it, some of them are mentioned below. Single direction control. If you want to rotate your motor in only one direction, then this is the easiest way to do so. Here power transistor is used as a switch to turn a motor on or off depending upon the applied voltage at base. Its circuit is shown below. The same motor driver circuit is used in making a simple line follower robot. One direction motor control. Working of above circuit. The figure below will describe its working. Working. Note Check the rating of the transistor you are using. It must be greater than the maximum current drawn by your motor. A normal DC motor as shown below draws 2. A current. D8. 80 transistor has a max collector current rating of 3. A. Gear head motor. Voltage Controlled Pwm Driver' title='Voltage Controlled Pwm Driver' /> ON Semiconductor provides new semiconductors for use as active electrical components. The Automotive PWM BiDirectional Controller and DRIVER is a complete autorepair and diagnostic tool meant to power high current. Why is there a need for a motor driver circuit Normal DC gearhead motors requires current greater than 250mA. ICs like 555 timer, ATmega16 Microcontroller, 74. Alternatively, a MOSFET driver which includes a PWM generator can be used. I know of only one which is not yet released The SGS Thomson TD340. Circuits/Interface/pwm_motor.png' alt='Voltage Controlled Pwm Driver' title='Voltage Controlled Pwm Driver' />Use power transistors, as chances of their damage is less in case of a short circuit due to the heat sink attached to them. If the current requirement is higher, then use Relays. Both direction control H Bridge circuitFor controlling motor in both directions H bridge circuit is used. Its working is very simple and is described below. H bridge working. Closed Switches. Open Switches. Voltage across motor. Motion. Nil. S1,S2,S3,S4. Voltage Controlled Pwm Driver' title='Voltage Controlled Pwm Driver' />

ON Semiconductor provides new semiconductors for use as active electrical components. The Automotive PWM BiDirectional Controller and DRIVER is a complete autorepair and diagnostic tool meant to power high current. Why is there a need for a motor driver circuit Normal DC gearhead motors requires current greater than 250mA. ICs like 555 timer, ATmega16 Microcontroller, 74. Alternatively, a MOSFET driver which includes a PWM generator can be used. I know of only one which is not yet released The SGS Thomson TD340. Circuits/Interface/pwm_motor.png' alt='Voltage Controlled Pwm Driver' title='Voltage Controlled Pwm Driver' />Use power transistors, as chances of their damage is less in case of a short circuit due to the heat sink attached to them. If the current requirement is higher, then use Relays. Both direction control H Bridge circuitFor controlling motor in both directions H bridge circuit is used. Its working is very simple and is described below. H bridge working. Closed Switches. Open Switches. Voltage across motor. Motion. Nil. S1,S2,S3,S4. Voltage Controlled Pwm Driver' title='Voltage Controlled Pwm Driver' /> Hi Friends, in my last post of Simple DC motor Control, Ive discussed controlling a small DC motor using the PWM method with MOSFET Hbridge. The circuit was build. The TB6612FNG motor driver can control up to two DC motors at a constant current of 1. A 3. 2A peak. Two input signals IN1 and IN2 can be used to contro. The LTC6992 is a silicon oscillator with an easytouse analog voltagecontrolled pulse width modulation PWM capability. No motion. S1,S4. S2,S3. 12. V sayClockwise sayS2,S3. S1,S4 1. 2VAnti clockwise. S1,S3. S2,S4. 0VBrake. So there are four possible conditions out of 1. This is met by using 2 npn and 2 pnp transistor as shown below. Transistor H bridge. I1. I2. ABMotion. Logic 0. Logic 0. Inductor switch mode buck converter for high energy efficiency. Wide supply voltage range of 5 to 20V. Great with batteries as well as AC adaptors. Stop. Logic 1. Logic 0. V0. Clockwise. Logic 0. Logic 1. 01. 2VAnti clockwise. Logic 1. Logic 1. V1. 2VBrake. Logic 1 means 5. V and Logic 0 means GND. Choose npn and pnp power transistors according to the current requirement of the motor under load. The above circuit works well but L2. L2. 93. D ICs are prefered over them, as they are compact and offer PWM channels to control motors speed. Using L2. 93. DL2. L2. 93. D and L2. H bridge motor driver ICs. We can control the rotation of two motors in both clockwise and anti clockwise direction. The pin outs of both ICs are shown below along with their differences. L2. 93. D pin configuration. L2. 98 pin configuration. Main difference between L2. Bmx Mountain Bike Games. D and L2. 98. Characteristic. L2. 98. L2. 93. DContinuous max. A 0. 6. A Peak max. A 1. A Protection diodes across motors. Use externally Internally available Source L2. D and L2. 98 datasheets. Here we prefer L2. D as a rating of 6. A is good for driving small DC motors and protection diodes are included in the IC itself. The description of each pin is as follows Enable pins These are pin no. Pin no. 1 is used to enable Half H driver 1 and 2. H bridge on Left side. Pin no. 9 is used to enable H bridge driver 3and 4. H bridge on right side. The concept is simple, if you want to use a particular H bridge you have to give a high logic to corresponding enable pins along with the power supply to the IC. This pin can also be used to control speed of the motor using PWM technique. VCC1 Pin 1. 6 Power supply pin. Connect it to 5. V supply. VCC2 Pin 8 Power supply for motor. Apply ve voltage to it as per motor rating. If you want to drive your motor at 1. Jet.Oledb.4.0 Windows 7 64 Bit'>Jet.Oledb.4.0 Windows 7 64 Bit. V, apply 1. 2V on this pin. It is also possible to drive motor directly on a battery, other than the one used for supplying power to the circuit, Just connect ve terminal of that battery to VCC2 pin and make GND of both the batteries common. MAX voltage at this pin is 3. V as per its datasheet. GND Pins 4,5,1. 2,1. Connect them to common GND of circuit. Inputs Pins 2,7,1. These are input pins through which control signals are given by microcontrollers or other circuitsICs. For example, if on pin 2 Input of 1st half H driver we give Logic 1 5. V, we will get a voltage equal to VCC2 on corresponding output pin of 1st half H driver i. Similarly for Logic 0 0. V on Pin 2, 0. V on Pin 3 appears. Outputs Pin 3,6,1. Outputs pins. According to input signal output signal comes. Circuit diagram Circuit diagram. A2. A1. Y2. YMotor 1. Logic 0. Logic 0. Stop. Logic 1. Logic 0. V0. Clockwise. Logic 0. Logic 1. 01. 2VAnti clockwise. Logic 1. Logic 1. V1. 2VBrake. For driving high power motors relays are used like cars Wiper motor. Using Relays. Relays are electromechanical switches. They have very high current rating and both AC and DC motors can be controlled through them because motor will be completely isolated from the remaining circuit. Two common available SPDT relays are shown in the picture below. Working of relay. Working of a relay Relays consist of a electromagnet, armature, spring and electrical contacts. The spring holds the armature at one electrical contact and as soon as a voltage is applied across the electromagnet, it coils the armature, changes its contact and moves to another electrical contact. The figure below describes its working. Relays. Terms associated with relays Normally Open NO contacts connect the circuit when the relay is activated the circuit is disconnected when the relay is inactive. Normally ClosedNC contacts disconnect the circuit when the relay is activated the circuit is connected when the relay is inactive. Change Over CO Its the common contact. COIL Its the electromagnet coil inside relay. Relay ratings Coil rating Its the Voltage at which the coil gets fully activated. Some also have coil resistance mentioned on them. Relay coil voltage rated 6. V and 1. 2V are the most commonly available. Contact rating It depends on whether AC or DC current is passing through the contacts. The blue colored relay shown in the start of this page has a rating of 1. A at 1. 20. V AC, 5. A at 2. 50. V AC and 1. A at 2. 4V DC. Relay triggering circuit Depending upon a relays coil rating, some may require current greater than 1. A. If an IC cannot provide this much current, a transistor is used as a switch to trigger the relay as shown below. Dont avoid the protection diode D1 shown in circuit as it will protect transistor from back emf induced in relay coil. Relay triggering circuit. Switching speed of a relay is slow, around 1. Relays are used to drive an AC load from a small DC circuit, or to drive a high current consuming motors. Have you noticed a sound of tic tic while car wiper is on, This is the sound of relay inside the car that drives the wiper motor. Hope this was helpful to youVariable frequency drive Wikipedia. Small variable frequency drive. Chassis of above VFD cover removedA variable frequency drive VFD also termed adjustable frequency drive, variable speed drive, AC drive, micro drive or inverter drive is a type of adjustable speed drive used in electro mechanical drive systems to control AC motorspeed and torque by varying motor input frequency and voltage. VFDs are used in applications ranging from small appliances to large compressors. About 2. 5 of the worlds electrical energy is consumed by electric motors in industrial applications, which can be more efficient when using VFDs in centrifugal load service 5 however, VFDs global market penetration for all applications is relatively small. Over the last four decades, power electronics technology has reduced VFD cost and size and has improved performance through advances in semiconductor switching devices, drive topologies, simulation and control techniques, and control hardware and software. VFDs are made in a number of different low and medium voltage AC AC and DC AC topologies. System description and operationeditA variable frequency drive is a device used in a drive system consisting of the following three main sub systems AC motor, main drive controller assembly, and driveoperator interface. AC motoreditThe AC electric motor used in a VFD system is usually three phaseinduction motor. Some types of single phase motors or synchronous motors advantageous in some situations can be used, but three phase induction motors are generally preferred as the most economical motor choice. Motors that are designed for fixed speed operation are often used. Elevated voltage stresses imposed on induction motors that are supplied by VFDs require that such motors be designed for definite purpose inverter fed duty in accordance with such requirements as Part 3. NEMA Standard MG 1. ControllereditThe VFD controller is a solid state power electronics conversion system consisting of three distinct sub systems a rectifier bridge converter, a direct current DC link, and an inverter. Voltage source inverter VSI drives see Generic topologies sub section below are by far the most common type of drives. Most drives are AC AC drives in that they convert AC line input to AC inverter output. However, in some applications such as common DC bus or solar applications, drives are configured as DC AC drives. The most basic rectifier converter for the VSI drive is configured as a three phase, six pulse, full wavediode bridge. In a VSI drive, the DC link consists of a capacitor which smooths out the converters DC output ripple and provides a stiff input to the inverter. This filtered DC voltage is converted to quasi sinusoidal AC voltage output using the inverters active switching elements. VSI drives provide higher power factor and lower harmonic distortion than phase controlledcurrent source inverter CSI and load commutated inverter LCI drives see Generic topologies sub section below. The drive controller can also be configured as a phase converter having single phase converter input and three phase inverter output. Controller advances have exploited dramatic increases in the voltage and current ratings and switching frequency of solid state power devices over the past six decades. Introduced in 1. 98. IGBT has in the past two decades come to dominate VFDs as an inverter switching device. In variable torque applications suited for Volts per Hertz VHz drive control, AC motor characteristics require that the voltage magnitude of the inverters output to the motor be adjusted to match the required load torque in a linear VHz relationship. For example, for 4. V, 6. 0 Hz motors, this linear VHz relationship is 4. VHz. While suitable in wide ranging applications, VHz control is sub optimal in high performance applications involving low speed or demanding, dynamic speed regulation, positioning, and reversing load requirements. Some VHz control drives can also operate in quadratic VHz mode or can even be programmed to suit special multi point VHz paths. The two other drive control platforms, vector control and direct torque control DTC, adjust the motor voltage magnitude, angle from reference, and frequency1. Although space vectorpulse width modulation SVPWM is becoming increasingly popular,1. PWM SPWM is the most straightforward method used to vary drives motor voltage or current and frequency. With SPWM control see Fig. Operation of the motors above rated nameplate speed base speed is possible, but is limited to conditions that do not require more power than the nameplate rating of the motor. This is sometimes called field weakening and, for AC motors, means operating at less than rated VHz and above rated nameplate speed. Permanent magnet synchronous motors have quite limited field weakening speed range due to the constant magnet flux linkage. Wound rotor synchronous motors and induction motors have much wider speed range. For example, a 1. HP, 4. 60 V, 6. 0 Hz, 1. RPM 4 pole induction motor supplied with 4. V, 7. 5 Hz 6. 1. VHz, would be limited to 6. RPM 1. 00 power. 1. At higher speeds, the induction motor torque has to be limited further due to the lowering of the breakaway torquea of the motor. Thus, rated power can be typically produced only up to 1. Wound rotor synchronous motors can be run at even higher speeds. In rolling mill drives, often 2. The mechanical strength of the rotor limits the maximum speed of the motor. Fig. 1 SPWM carrier sine input 2 level PWM output. An embeddedmicroprocessor governs the overall operation of the VFD controller. Basic programming of the microprocessor is provided as user inaccessible firmware. User programming of display, variable, and function block parameters is provided to control, protect, and monitor the VFD, motor, and driven equipment. The basic drive controller can be configured to selectively include such optional power components and accessories as follows Operator interfaceeditThe operator interface provides a means for an operator to start and stop the motor and adjust the operating speed. Additional operator control functions might include reversing, and switching between manual speed adjustment and automatic control from an external process control signal. The operator interface often includes an alphanumeric display or indication lights and meters to provide information about the operation of the drive. An operator interface keypad and display unit is often provided on the front of the VFD controller as shown in the photograph above. The keypad display can often be cable connected and mounted a short distance from the VFD controller. Most are also provided with input and output IO terminals for connecting push buttons, switches, and other operator interface devices or control signals. A serial communicationsport is also often available to allow the VFD to be configured, adjusted, monitored, and controlled using a computer. Drive operationedit. Electric motor speed torque chart. Referring to the accompanying chart, drive applications can be categorized as single quadrant, two quadrant, or four quadrant the charts four quadrants are defined as follows 2. Quadrant I Driving or motoring,2. Quadrant II Generating or braking, forward braking decelerating quadrant with positive speed and negative torque.

Hi Friends, in my last post of Simple DC motor Control, Ive discussed controlling a small DC motor using the PWM method with MOSFET Hbridge. The circuit was build. The TB6612FNG motor driver can control up to two DC motors at a constant current of 1. A 3. 2A peak. Two input signals IN1 and IN2 can be used to contro. The LTC6992 is a silicon oscillator with an easytouse analog voltagecontrolled pulse width modulation PWM capability. No motion. S1,S4. S2,S3. 12. V sayClockwise sayS2,S3. S1,S4 1. 2VAnti clockwise. S1,S3. S2,S4. 0VBrake. So there are four possible conditions out of 1. This is met by using 2 npn and 2 pnp transistor as shown below. Transistor H bridge. I1. I2. ABMotion. Logic 0. Logic 0. Inductor switch mode buck converter for high energy efficiency. Wide supply voltage range of 5 to 20V. Great with batteries as well as AC adaptors. Stop. Logic 1. Logic 0. V0. Clockwise. Logic 0. Logic 1. 01. 2VAnti clockwise. Logic 1. Logic 1. V1. 2VBrake. Logic 1 means 5. V and Logic 0 means GND. Choose npn and pnp power transistors according to the current requirement of the motor under load. The above circuit works well but L2. L2. 93. D ICs are prefered over them, as they are compact and offer PWM channels to control motors speed. Using L2. 93. DL2. L2. 93. D and L2. H bridge motor driver ICs. We can control the rotation of two motors in both clockwise and anti clockwise direction. The pin outs of both ICs are shown below along with their differences. L2. 93. D pin configuration. L2. 98 pin configuration. Main difference between L2. Bmx Mountain Bike Games. D and L2. 98. Characteristic. L2. 98. L2. 93. DContinuous max. A 0. 6. A Peak max. A 1. A Protection diodes across motors. Use externally Internally available Source L2. D and L2. 98 datasheets. Here we prefer L2. D as a rating of 6. A is good for driving small DC motors and protection diodes are included in the IC itself. The description of each pin is as follows Enable pins These are pin no. Pin no. 1 is used to enable Half H driver 1 and 2. H bridge on Left side. Pin no. 9 is used to enable H bridge driver 3and 4. H bridge on right side. The concept is simple, if you want to use a particular H bridge you have to give a high logic to corresponding enable pins along with the power supply to the IC. This pin can also be used to control speed of the motor using PWM technique. VCC1 Pin 1. 6 Power supply pin. Connect it to 5. V supply. VCC2 Pin 8 Power supply for motor. Apply ve voltage to it as per motor rating. If you want to drive your motor at 1. Jet.Oledb.4.0 Windows 7 64 Bit'>Jet.Oledb.4.0 Windows 7 64 Bit. V, apply 1. 2V on this pin. It is also possible to drive motor directly on a battery, other than the one used for supplying power to the circuit, Just connect ve terminal of that battery to VCC2 pin and make GND of both the batteries common. MAX voltage at this pin is 3. V as per its datasheet. GND Pins 4,5,1. 2,1. Connect them to common GND of circuit. Inputs Pins 2,7,1. These are input pins through which control signals are given by microcontrollers or other circuitsICs. For example, if on pin 2 Input of 1st half H driver we give Logic 1 5. V, we will get a voltage equal to VCC2 on corresponding output pin of 1st half H driver i. Similarly for Logic 0 0. V on Pin 2, 0. V on Pin 3 appears. Outputs Pin 3,6,1. Outputs pins. According to input signal output signal comes. Circuit diagram Circuit diagram. A2. A1. Y2. YMotor 1. Logic 0. Logic 0. Stop. Logic 1. Logic 0. V0. Clockwise. Logic 0. Logic 1. 01. 2VAnti clockwise. Logic 1. Logic 1. V1. 2VBrake. For driving high power motors relays are used like cars Wiper motor. Using Relays. Relays are electromechanical switches. They have very high current rating and both AC and DC motors can be controlled through them because motor will be completely isolated from the remaining circuit. Two common available SPDT relays are shown in the picture below. Working of relay. Working of a relay Relays consist of a electromagnet, armature, spring and electrical contacts. The spring holds the armature at one electrical contact and as soon as a voltage is applied across the electromagnet, it coils the armature, changes its contact and moves to another electrical contact. The figure below describes its working. Relays. Terms associated with relays Normally Open NO contacts connect the circuit when the relay is activated the circuit is disconnected when the relay is inactive. Normally ClosedNC contacts disconnect the circuit when the relay is activated the circuit is connected when the relay is inactive. Change Over CO Its the common contact. COIL Its the electromagnet coil inside relay. Relay ratings Coil rating Its the Voltage at which the coil gets fully activated. Some also have coil resistance mentioned on them. Relay coil voltage rated 6. V and 1. 2V are the most commonly available. Contact rating It depends on whether AC or DC current is passing through the contacts. The blue colored relay shown in the start of this page has a rating of 1. A at 1. 20. V AC, 5. A at 2. 50. V AC and 1. A at 2. 4V DC. Relay triggering circuit Depending upon a relays coil rating, some may require current greater than 1. A. If an IC cannot provide this much current, a transistor is used as a switch to trigger the relay as shown below. Dont avoid the protection diode D1 shown in circuit as it will protect transistor from back emf induced in relay coil. Relay triggering circuit. Switching speed of a relay is slow, around 1. Relays are used to drive an AC load from a small DC circuit, or to drive a high current consuming motors. Have you noticed a sound of tic tic while car wiper is on, This is the sound of relay inside the car that drives the wiper motor. Hope this was helpful to youVariable frequency drive Wikipedia. Small variable frequency drive. Chassis of above VFD cover removedA variable frequency drive VFD also termed adjustable frequency drive, variable speed drive, AC drive, micro drive or inverter drive is a type of adjustable speed drive used in electro mechanical drive systems to control AC motorspeed and torque by varying motor input frequency and voltage. VFDs are used in applications ranging from small appliances to large compressors. About 2. 5 of the worlds electrical energy is consumed by electric motors in industrial applications, which can be more efficient when using VFDs in centrifugal load service 5 however, VFDs global market penetration for all applications is relatively small. Over the last four decades, power electronics technology has reduced VFD cost and size and has improved performance through advances in semiconductor switching devices, drive topologies, simulation and control techniques, and control hardware and software. VFDs are made in a number of different low and medium voltage AC AC and DC AC topologies. System description and operationeditA variable frequency drive is a device used in a drive system consisting of the following three main sub systems AC motor, main drive controller assembly, and driveoperator interface. AC motoreditThe AC electric motor used in a VFD system is usually three phaseinduction motor. Some types of single phase motors or synchronous motors advantageous in some situations can be used, but three phase induction motors are generally preferred as the most economical motor choice. Motors that are designed for fixed speed operation are often used. Elevated voltage stresses imposed on induction motors that are supplied by VFDs require that such motors be designed for definite purpose inverter fed duty in accordance with such requirements as Part 3. NEMA Standard MG 1. ControllereditThe VFD controller is a solid state power electronics conversion system consisting of three distinct sub systems a rectifier bridge converter, a direct current DC link, and an inverter. Voltage source inverter VSI drives see Generic topologies sub section below are by far the most common type of drives. Most drives are AC AC drives in that they convert AC line input to AC inverter output. However, in some applications such as common DC bus or solar applications, drives are configured as DC AC drives. The most basic rectifier converter for the VSI drive is configured as a three phase, six pulse, full wavediode bridge. In a VSI drive, the DC link consists of a capacitor which smooths out the converters DC output ripple and provides a stiff input to the inverter. This filtered DC voltage is converted to quasi sinusoidal AC voltage output using the inverters active switching elements. VSI drives provide higher power factor and lower harmonic distortion than phase controlledcurrent source inverter CSI and load commutated inverter LCI drives see Generic topologies sub section below. The drive controller can also be configured as a phase converter having single phase converter input and three phase inverter output. Controller advances have exploited dramatic increases in the voltage and current ratings and switching frequency of solid state power devices over the past six decades. Introduced in 1. 98. IGBT has in the past two decades come to dominate VFDs as an inverter switching device. In variable torque applications suited for Volts per Hertz VHz drive control, AC motor characteristics require that the voltage magnitude of the inverters output to the motor be adjusted to match the required load torque in a linear VHz relationship. For example, for 4. V, 6. 0 Hz motors, this linear VHz relationship is 4. VHz. While suitable in wide ranging applications, VHz control is sub optimal in high performance applications involving low speed or demanding, dynamic speed regulation, positioning, and reversing load requirements. Some VHz control drives can also operate in quadratic VHz mode or can even be programmed to suit special multi point VHz paths. The two other drive control platforms, vector control and direct torque control DTC, adjust the motor voltage magnitude, angle from reference, and frequency1. Although space vectorpulse width modulation SVPWM is becoming increasingly popular,1. PWM SPWM is the most straightforward method used to vary drives motor voltage or current and frequency. With SPWM control see Fig. Operation of the motors above rated nameplate speed base speed is possible, but is limited to conditions that do not require more power than the nameplate rating of the motor. This is sometimes called field weakening and, for AC motors, means operating at less than rated VHz and above rated nameplate speed. Permanent magnet synchronous motors have quite limited field weakening speed range due to the constant magnet flux linkage. Wound rotor synchronous motors and induction motors have much wider speed range. For example, a 1. HP, 4. 60 V, 6. 0 Hz, 1. RPM 4 pole induction motor supplied with 4. V, 7. 5 Hz 6. 1. VHz, would be limited to 6. RPM 1. 00 power. 1. At higher speeds, the induction motor torque has to be limited further due to the lowering of the breakaway torquea of the motor. Thus, rated power can be typically produced only up to 1. Wound rotor synchronous motors can be run at even higher speeds. In rolling mill drives, often 2. The mechanical strength of the rotor limits the maximum speed of the motor. Fig. 1 SPWM carrier sine input 2 level PWM output. An embeddedmicroprocessor governs the overall operation of the VFD controller. Basic programming of the microprocessor is provided as user inaccessible firmware. User programming of display, variable, and function block parameters is provided to control, protect, and monitor the VFD, motor, and driven equipment. The basic drive controller can be configured to selectively include such optional power components and accessories as follows Operator interfaceeditThe operator interface provides a means for an operator to start and stop the motor and adjust the operating speed. Additional operator control functions might include reversing, and switching between manual speed adjustment and automatic control from an external process control signal. The operator interface often includes an alphanumeric display or indication lights and meters to provide information about the operation of the drive. An operator interface keypad and display unit is often provided on the front of the VFD controller as shown in the photograph above. The keypad display can often be cable connected and mounted a short distance from the VFD controller. Most are also provided with input and output IO terminals for connecting push buttons, switches, and other operator interface devices or control signals. A serial communicationsport is also often available to allow the VFD to be configured, adjusted, monitored, and controlled using a computer. Drive operationedit. Electric motor speed torque chart. Referring to the accompanying chart, drive applications can be categorized as single quadrant, two quadrant, or four quadrant the charts four quadrants are defined as follows 2. Quadrant I Driving or motoring,2. Quadrant II Generating or braking, forward braking decelerating quadrant with positive speed and negative torque.